DTF Transfer Technology Guide: Revolutionize Your T-Shirt Printing Operation in 2025

The DTF transfer method has revolutionized the t-shirt printing business, offering unmatched flexibility and excellence for companies large and small. As we progress into 2025, DTF transfers have emerged as the top choice for generating colorful, resilient graphics on practically all fabric material. Whether you're a experienced garment decorator or launching your business in custom apparel, mastering the capabilities of DTF printing technology is crucial for maintaining your edge in this dynamic industry.

DTF Printing Explained Understanding the Technology

DTF printing is an cutting-edge digital printing method that involves producing designs on special PET film using water-based inks and bonding powder. Different from standard printing processes, DTF transfers can be transferred onto multiple fabric types from natural to synthetic without pre-treatment. This flexibility makes DTF printer technology increasingly popular among businesses looking for streamlined, professional printing options.

The process generates prints that are not only visually stunning but also extremely long-lasting. DTF transfers resist cracking, peeling, and fading even after repeated laundering, making them excellent for commercial applications where durability is critical. With the ability to create detailed artwork, gradients, and photorealistic images, DTF printing provides infinite creative options for your business.

The DTF Transfer Process: Detailed Instructions

Making professional-quality DTF transfers demands mastering each step of the process. Here's a thorough breakdown:

1. Design Creation and Preparation

First creating your design using design programs like professional design tools, or user-friendly alternatives like Canva or Procreate. Output your design as a high-resolution PNG file with a transparent background. The advantage of DTF printing is that you can use detailed multicolor graphics without concerning yourself with color restrictions.

2. The Printing Process

Import your design into the DTF printer software. The printer will begin by lay down the color layers (CMYK) directly onto the PET film, then add a white ink layer that functions as a base. This white layer is vital for achieving vibrant colors on dark fabrics. Contemporary DTF printer models can reach speeds of up to 40 linear meters per minute, making them perfect for mass production.

3. Adding the Bonding Agent

When the ink is still wet, uniformly spread hot-melt adhesive powder across the entire printed design. This powder is what attaches the DTF transfer to the fabric during heat pressing. Use a back-and-forth movement to achieve complete coverage, then remove any excess powder. Many companies are now investing in automated powder shakers for uniform results.

4. Powder Activation

The adhesive powder requires heat-activated before application. This can be achieved using a curing oven (recommended for safety and efficiency) or by using a heat press. Curing generally takes 60-90 seconds in an oven at the correct temperature. Proper curing ensures your DTF transfers can be kept for later use or applied immediately.

5. Heat Press Application

First press your garment for 10 seconds to remove moisture and wrinkles. Position your DTF transfer on the fabric and press at appropriate temperature for quarter minute with balanced pressure. The heat engages the adhesive, creating a lasting connection between the design and fabric.

6. Peeling and Final Press

Once pressed, remove the film while it's still heated in one smooth motion. This hot-peel process delivers clean edges and eliminates unwanted lines in your design. To finish, complete a second press for another 10-15 seconds to enhance durability and minimize shine.

Why DTF Printing is Dominating the Market in 2025

The DTF printing market has witnessed remarkable expansion, valued at $2.72 billion in 2024 and expected to reach impressive heights by 2030. This impressive development is fueled by several critical drivers:

Superior Flexibility

In contrast with other printing methods, DTF transfers apply to almost every fabric textile without preparation. From pure cotton to artificial fabrics, various materials, DTF printing ensures consistent, high-quality results across all surfaces.

Flexible Order Quantities

If you require individual items or bulk orders, DTF printer technology abolishes setup costs and volume requirements. This adaptability makes it ideal for print-on-demand, individual designs, and testing new designs without monetary commitment.

Superior Print Quality

Contemporary DTF printing generates exceptionally sharp, bright graphics that match or surpass standard processes. The technology specializes in creating photographic images, smooth color transitions, and precise features that would be difficult with screen printing or vinyl cutting.

Cost-Effective Production

With minimal startup expenses than screen printing and speedier output than DTG printing, DTF transfers provide an superior ROI. The option to combine various graphics on a one film also decreases costs and supply usage.

Necessary Hardware for Professional Results

To launch your DTF printing business, you'll want the following machinery:

- DTF Printer: Pick between specialized printers by manufacturers like top manufacturers, or convert existing printers for DTF printing

- DTF Inks: Specialized textile inks developed for optimal adhesion and color vibrancy

- Transfer Film: Offered as rolls or sheets, with varied peel options

- Transfer Powder: Light powder for most applications, alternative powder for dark designs on dark fabrics

- Transfer Press: Industrial press with consistent temperature and pressure

- Powder Dryer: For proper powder curing (strongly advised)

- RIP Software: For color management and print optimization

Market Evolution Leading Innovation

Sustainability Focus

The sector is embracing eco-friendly practices with water-based inks, biodegradable films, and energy-efficient processes. Consumers are more frequently requesting sustainable products, making eco-consciousness a major advantage for DTF printing businesses.

Smart Manufacturing

Sophisticated DTF printer machines now feature smart design tools, robotic powder spreading, and smart diagnostics. These advancements minimize workforce needs while boosting reliability and result standards.

Personalization at Scale

The power to manufacture unique designs at the same speed as regular production is revolutionizing the business. DTF transfers enable operations to deliver true personalization without compromising output rate.

Maximizing Your DTF Investment

To thrive with DTF printing, implement these best practices:

- Choose premium DTF printer equipment and materials for reliable output

- Properly care for your machinery to eliminate interruptions

- Fine-tune your workflow by ganging designs on single sheets

- Remain informed on market developments and new DTF printing techniques

- Connect with quality providers for consistent inventory

- Train your team on proper DTF transfers techniques

What's Next for DTF

As we progress, DTF printing continues to evolve with groundbreaking changes. Industry experts forecast sustained development in sector dominance, with DTF transfers becoming the benchmark for textile printing.

Whether you're ready to start your DTF printing business or wanting to enhance your present system, now is the optimal opportunity to invest in this game-changing technology. With the right machinery, knowledge, and focus, your DTF printer can function as the cornerstone of a profitable custom apparel business.

Begin Your Journey

Upgrade your printing business with industry-leading DTF transfers. Get in touch to explore about our full selection of DTF printing equipment and begin producing stunning personalized garments today!

Daniel Stern Then & Now!

Daniel Stern Then & Now! Ashley Johnson Then & Now!

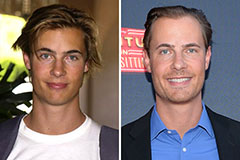

Ashley Johnson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!